Suppressing thermal emission loss—also regarded as blackbody radiation—while simultaneously absorbing photo voltaic light is significant for an effective photo voltaic thermal absorber but is extremely complicated to realize, claims Baohua Jia, founding director of CTAM. “That’s for the reason that, depending on the absorbed heat and houses of the absorber, the emission temperature differs, which leads to considerable differences in its wavelength,” she clarifies. “But we have produced a a few-dimensional structured graphene metamaterial (SGM) that is very absorbent and selectively filters out blackbody radiation.”

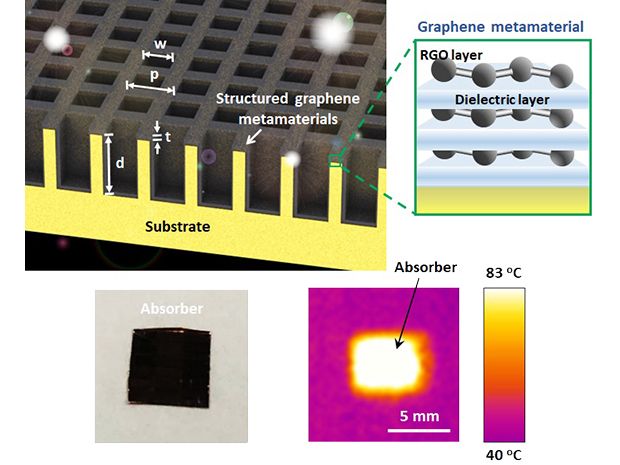

The 3D SGM is composed of a thirty-nanometer-thick film of alternating graphene and dielectric levels deposited on a trench-like nanostructure that does double responsibility as a copper substrate to enrich absorption. Much more importantly, the substrate is patterned in a matrix arrangement to help versatile tunability of wavelength-selective absorption.

The graphene film is made to take in light concerning .28- to two.5-micrometer wavelengths. And the copper substrate is structured so that it can act as a selective bandpass filter that suppresses the normal emission of internally generated blackbody vitality. This retained heat then serves to further increase the metamaterial’s temperature. That’s why, the SGM can quickly heat up to 83 degrees C. Should really a different temperature be essential for a specific software, a new trench nanostructure can be fabricated and tuned to match that particular blackbody wavelength.

“In our previous work, we shown a 90 nm graphene heat-absorbing content,” claims Baohua. Although it could heat up to one hundred sixty degrees C, “the construction was additional complex, [comprising] four levels: a substrate, a silver layer, a layer of silicon oxide, and a graphene layer. Our new two-layer construction is less complicated and does not call for vacuum deposition. And the system of fabrication is scalable and reduced price tag.”

The new content also uses less graphene by substantially lessening the film thickness to one 3rd, and its thinness aids in transferring the absorbed heat additional effectively to other media such as h2o. On top of that, the film is hydrophobic, which fosters self-cleaning, although the graphene layer properly guards the copper layer from corrosion, supporting to extend the metamaterial’s life time.

“Because the steel substrate’s structural parameters are the principal things governing all round absorption overall performance of the SGM, relatively than its intrinsic options, different metals can be employed in accordance to software desires or price tag,” claims Keng-Te Lin, direct author of a paper on the metamaterial lately posted in Mother nature Communications, and who is also a investigate fellow at Swinburne University. Aluminum foil can also be employed to replace copper without having compromising the overall performance, he notes.

To check the metamaterial’s layout and security, the researchers fabricated a prototype applying regular laser nanofabrication, self-assembly graphene oxide coating, and picture-induced reduction.

“We employed the prototype film to make clean up h2o and achieved an outstanding photo voltaic-to-vapor effectiveness of ninety six.two %,” claims Keng-Te. “This is pretty competitive for clean up h2o generation applying a renewable vitality resource.”

He provides that the metamaterial can also be employed for vitality harvesting and conversion apps, steam generation, wastewater cleaning, seawater desalination, and thermoelectricity generation.

1 problem nevertheless remaining is getting a manufacturing system for creating the substrate scalable.

“We are working with a non-public enterprise, Innofocus Photonics Technologies, that has commercialized a coating machine to lay down the graphene and dielectric levels,” claims Baohua. “And we are happy with that. What we are now hunting for is a suited system for large scale production of the copper substrate.” 1 possibility, she provides, is applying a roll-to-roll course of action.

In the meantime, the researchers are continuing to great-tune the nanostructure layout and make improvements to the SGM’s security and absorption effectiveness. “As for commercialization,” claims Baohua, “we believe that will be feasible in one to two several years.”

More Stories

Video Doorbells – Now You’ll Know Who’s There

The Fifth Wave: Fifth Industrial Revolution

Einstein – Definition of Insanity