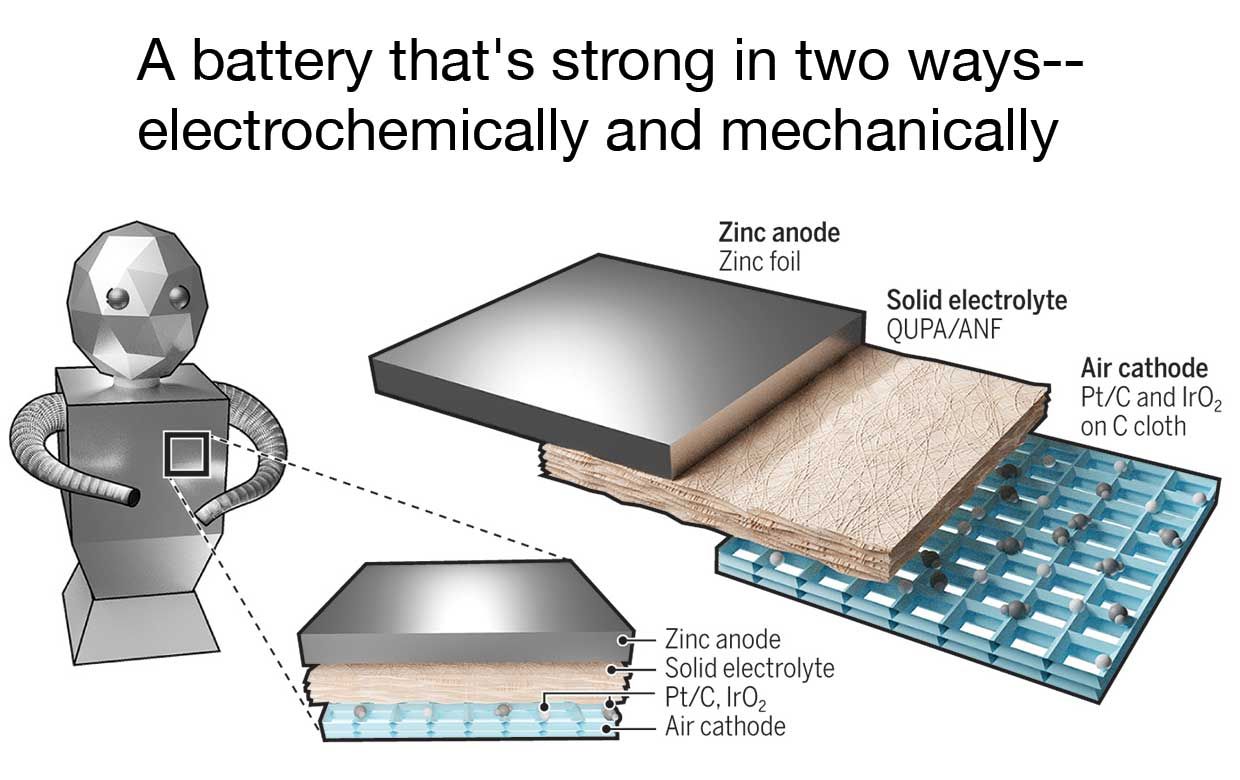

Batteries can insert considerable mass to any structure, and they have to be supported applying a sufficiently sturdy framework, which can insert considerable mass of its very own. Now scientists at the College of Michigan have designed a structural zinc-air battery, one particular that integrates straight into the device that it powers and serves as a load-bearing component.

That feature saves excess weight and consequently increases effective storage ability, adding to the now hefty electricity density of the zinc-air chemistry. And the extremely components that make the battery physically sturdy support have the chemistry’s longstanding inclination to degrade over a lot of hundreds of charge-discharge cycles.

The exploration is being printed right now in Science Robotics.

Nicholas Kotov, a professor of chemical engineer, is the leader of the project. He would not say how a lot of watt-several hours his prototype suppliers for every gram, but he did note that zinc air—because it draw on ambient air for its electricity-making reactions—is inherently about three times as electricity-dense as lithium-ion cells. And, due to the fact applying the battery as a structural part means dispensing with an interior battery pack, you could no cost up possibly 20 % of a machine’s interior. Along with other variables the new battery could in theory give as much as seventy two times the electricity for every unit of volume (not of mass) as today’s lithium-ion workhorses.

“It’s not as if we invented a thing that was there in advance of us,” Kotov suggests. ”I search in the mirror and I see my layer of fat—that’s for the storage of electricity, but it also serves other purposes,” like holding you heat in the wintertime. (A similar advance occurred in rocketry when designers uncovered how to make some liquid propellant tanks load bearing, removing the mass penalty of having individual exterior hull and internal tank walls.)

Other folks have spoken of putting batteries, together with the lithium-ion sort, into load-bearing areas in automobiles. Ford, BMW, and Airbus, for occasion, have expressed interest in the concept. The major issue to triumph over is the tradeoff in load-bearing batteries between electrochemical overall performance and mechanical strength.

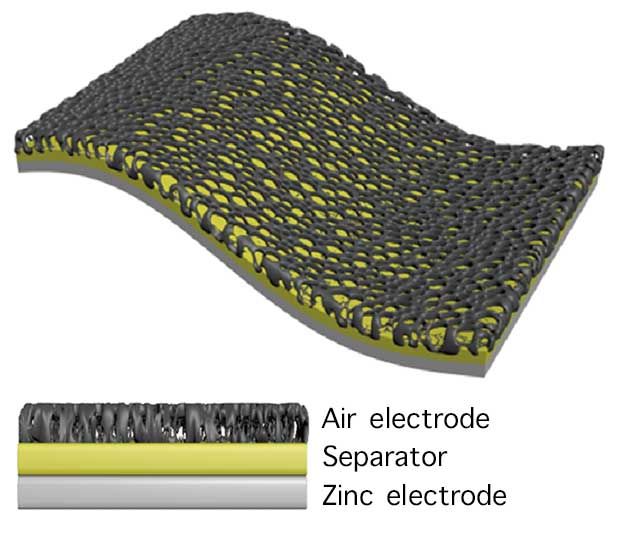

The Michigan group get the two characteristics by using a stable electrolyte (which can not leak under anxiety) and by covering the electrodes with a membrane whose nanostructure of fibers is derived from Kevlar. That will make the membrane difficult ample to suppress the expansion of dendrites—branching fibers of steel that are inclined to type on an electrode with just about every demand-discharge cycle and which degrade the battery.

The Kevlar need not be purchased new but can be salvaged from discarded system armor. Other production ways really should be quick, way too, Kotov suggests. He has only just started to converse to opportunity commercial associates, but he suggests there is no rationale why his battery couldn’t strike the current market in the following three or four decades.

Drones and other autonomous robots may well be the most sensible 1st application due to the fact their variety is so severely chained to their battery ability. Also, due to the fact this sort of robots really don’t have folks about, they deal with a lot less of a hurdle from basic safety regulators leery of a fundamentally new battery form.

“And it’s not just about the big Amazon robots but also extremely small ones,” Kotov suggests. “Energy storage is a extremely considerable challenge for small and adaptable comfortable robots.”

Here’s a video clip demonstrating how Kotov’s lab has utilised batteries to type the “exoskeleton” of robots that scuttle like worms or scorpions.

More Stories

What is Intellectual Property and 3 Key Issues About It

Snapshot: The Wacky History Behind 3D Television Technology

Civilian Applications of GPS Technology