Researchers have devised a straightforward procedure to get better treasured unusual earth features (REEs) from trash. Heating digital and industrial squander to intensely incredibly hot temperatures with flashes of electricity can extract a lot more than 2 times the quantity of REEs from the materials than has been attainable with past tactics.

REEs, a team of 17 elements, are important elements for technologies that make our environment run: smartphones, EV motors, and wind turbines, to title a number of. But extracting them from the earth is filthy business enterprise, resulting in environmental damage and tons of squander, including lower-level radioactive waste.

Then there are worldwide supply-chain concerns. Opposite to their identify, unusual earths are actually not that exceptional in Earth’s crust. China, however, has cornered the lion’s share of the market, mining over 70 p.c of the world’s REEs and processing an even increased proportion. To circumvent that stronghold, automakers outside the house China are making an attempt to make electric motors that never use scarce-earth-that contains long-lasting magnets. Meanwhile, Japan is trying to retrieve the metals from deep-sea mud, and the Metals Co. options to mine metallic nodules from the ocean flooring.

A a lot more sustainable remedy for getting exceptional earths is to recycle them from aged electronics and squander like fly ash, a by-item of burning coal. Salvaging them is challenging, nevertheless. REEs don’t dissolve quickly for separation from other resources. In fly ash, they are existing in the sort of phosphates that never quickly break down, and the ash particles are often encased in a layer of glass that sorts in the coal-burning furnace.

REE extraction approaches currently in use count on large quantities of caustic substances these as acids, and they are inefficient. “You need to have robust acids to pull them out,” suggests James Tour, a chemist at Rice University. “And robust acids can not even get through glass to get started leeching them out.”

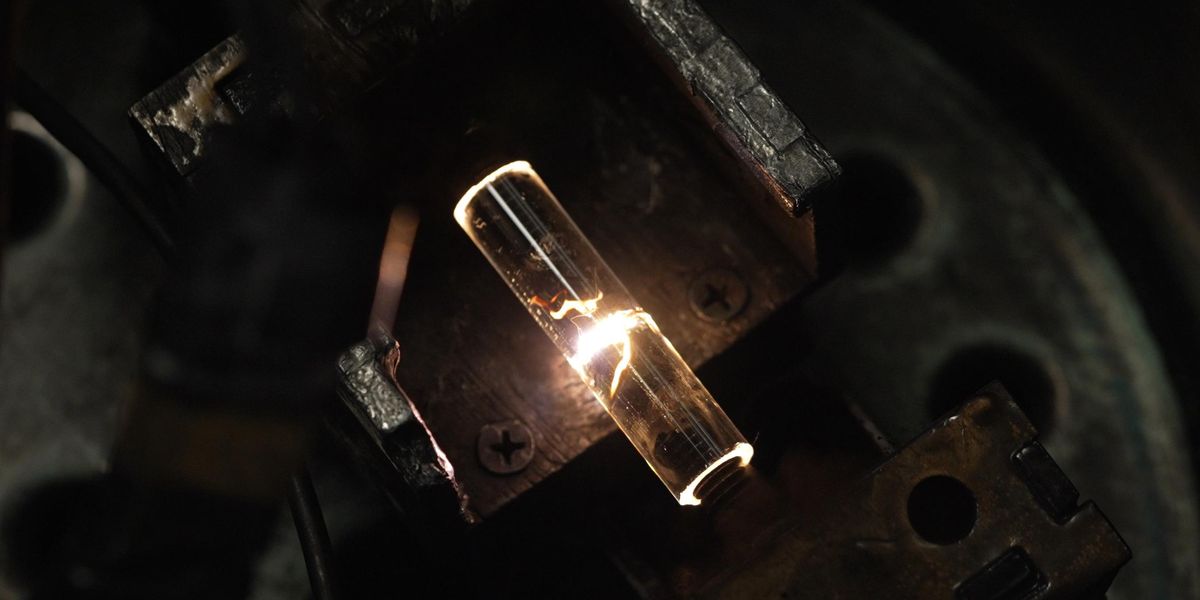

Tour and his colleagues decided to attempt employing the flash Joule heating system they originally produced in 2020 to make graphene from carbon resources. Past yr, they described working with the approach to take away treasured metals and harmful major metals from printed circuit boards. They’ve now determined to convert their notice to REE extraction. “We have the hammer we’re looking for nails,” Tour claims. “If we could choose trash and get from it these elements that we usually strip the earth for, that would be seriously great.”

In a paper printed in Science Improvements, they report working with flash Joule heating on coal fly ash, discarded printed circuit boards, and purple mud, the phrase for the iron-abundant slurry that is the by-product of aluminum manufacturing. These wastes consist of two to 3 moments as much of the 5 most significant REEs—yttrium, neodymium, europium, terbium, and dysprosium—as the total uncovered in some of the most concentrated ores in the entire world.

Zapping the waste components with limited, intense bursts of electricity quickly heats them to about 3,000 °C. That’s ample to crack the glass layer close to fly ash particles, and to convert the REE phosphates uncovered in equally fly ash and bauxite into oxides that dissolve simply in incredibly moderate acid for subsequent removal. In electronic squander, REEs are generally in the form of quick-to-dissolve REE metals or oxides, Tour suggests. But here is the rub: They are embedded into the matrix elements in layers, earning them continue to really hard to clear away. Flash Joule heating cracks and separates the matrix layers, generating REE separation and removing much easier.

As a outcome, the procedure is in a position to extract significantly more rare earths than the traditional method applying potent acids. “The concentrated acids that have been the gold conventional weren’t receiving all the REEs out of fly ash,” Tour says, “so we’re acquiring 150 to 200 percent generate compared to that earlier regular.” What is additional, the new strategy does not use considerably warmth, and the electricity it utilizes would charge US $12 for each tonne of fly ash when utilized on big scale.

Tour claims he and his colleagues’ new approach has caught the awareness of people today in the REE market. And from them he has acquired that this novel process will not be an finish-all. “This does not address everything,” he claims. “You still get mixtures of REEs and there are standard procedures for separating these, but these can be significant cost points as very well. So this provides a new device to deal with the trouble, but there are continue to other issues that have to be solved.”

Other scientists are also attempting to crack the difficulty of extracting REEs from waste. Past 7 days, a crew from Lawrence Livermore Nationwide Laboratory and Pennsylvania State University declared that they are operating with Western Exceptional Earths to create a system that works by using a recently found out organic protein to extract unusual earths. And the U.S. Office of Vitality announced that it programs to construct the 1st massive-scale facility to extract REEs and other critical metals from mine waste.

More Stories

MP3 Players – Knowing the Various Interesting Facts About These Gadgets

How Hotels Can Cope Up With the Airbnb Generation Through Information Outsourcing

Roaring Machines – James Bond Vehicles